| Products

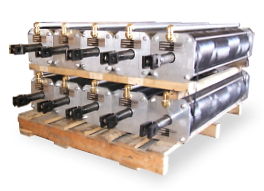

Capton Hydraulic Cylinders

Capton's Hydraulic Cylinders are

known for being one of the highest quality hydraulic cylinders

available. All materials and components used meet or exceed

industry standards. Take the gland and piston for example: the

material we use is Dura-bar ductile iron, the brand most ductile

iron manufacturers compare themselves to.

In nearly every application, Capton

hydraulic cylinders are equipped with a base plate that is thicker

than other manufacturers' for the same application. This reduces

stress resulting in a lifetime of leak free operation.

Another area Capton hydraulic

cylinders shine is the seals. Only high quality brand name seals,

rated for or above the cylinders operating pressure, are used.

This, combined with Capton's 2 year warranty*, gives you a

quality, dependable cylinder that is custom fit to your

application.

* All Capton cylinders up to

3000 psi operating pressure receive a 2 year warranty against

manufacturer's defects. All cylinders above 3000 psi

operating pressure are limited to 1 year warranty. Please contact

us for full warranty details.

Capton Pneumatic Cylinders

Capton Pneumatic Cylinders are a

good choice for any pneumatic application. As mentioned with

Capton hydraulic cylinders, Capton pneumatic cylinders are built

using only high quality components. All glands and pistons are

made of aircraft quality 6061 aluminum to reduce weight and

prevent corrosion. Once again, only high quality brand name

seals are used. On most cylinders, wear rings are standard items

on the gland and piston to prevent any metal to metal contact.

Capton Pneumatic Cylinders can

also be built as state-of-the-art composite tube cylinders...

What are the Advantages of

using Composite Tube Cylinders?

Applications Applications

Our composite tube cylinders can be used anywhere where weight and corrosion are an issue, for cylinders up to 2970 PSI operating pressure depending on tube diameter and wall thickness. They particularly shine in pneumatic applications.

They can be used in operating temperatures between -70°C

and +110°C

Light weight

The tubes weigh less than one

quarter, or 25%, of steel per volume, while providing over two

times the strength to weight ratio for internal pressure. The

tie rod design allows for thinner material to be used, which are

standard sizes with composite material. Our composite pneumatic

cylinders weigh approximately 25 to 40% less than pneumatic

cylinders with steel tube and snap ring design.

Long Lifetime

The smooth low-friction

bore offers decreased friction and increased

seal life. There is more power transmitted to the load and less

to friction. And unlike honed steel tubes, our composite

cylinders do not corrode.

High Strength, Low Maintenance

Never deal with refilling your

oiler or having rust on the inside of your cylinder again: our

composite cylinders are as strong as steel, never rust,

and could run on water! Since both the tube and guide rod

bushing are self lubricating, no oiler is required. Additionally,

they require no painting.

| Capton

Composite Tube Cylinder Specifications |

| Piston and Aluminum Ends |

Made out of aircraft quality

6061 T6 aluminum |

| Rod (shaft) |

Nitrided shaft for excellent dent

and corrosion protection |

| Tie rods |

Made out of 304 stainless steel, which exceeds mild steel strength and is cost effective compared with painting/powder coating steel tie rods. |

| Base Mounting Plate |

Painted with high quality Endura paint to eliminate

corrosion. |

| Piston Seals

|

U-cup seals provide less friction than o-ring seals. Lip design removes contamination versus O-ring tendency to rub particles into cylinder wall. Better sealing properties & increased seal life.

Guiding element eliminates

piston to cylinder wall contact. |

| Rod Seals |

Guide rod bushings are cost effective and allow close

tolerance between gland seal and rod while providing rod with full protection from metal contact. Also, guide rod bushings have built-in lubricating properties.

U-cup seal provides low friction, high quality sealing.

Double lip rod wiper effectively cleans rod and prevents contamination from passing around outside of wiper, which extends both wiper and rod seal life. Snap-in design makes installation and replacement a breeze. |

In order to reduce costs,

optional downgrades, such as chrome plated shaft and o-ring

seals, are available. Please contact us

or use the order form for more details and

to find out what will work best with your application.

|